| Corrugated Plate Static Mixer (Type GV) The GV static mixer has been used successfully in turbulent flow applications for over 35 years. It is a high performance inline mixer capable of mixing low viscosity liquids, blending gases, dispersing immiscible liquids and creating gas-liquid dispersions with a very high degree of mixing in a short length. |

|||

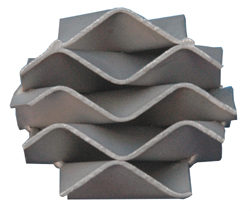

Figure #1: GV static mixer with 3-mixing elements, 5-corrugated mixing plates across its diameter and a 45o corrugation angle relative to the pipe axis. |

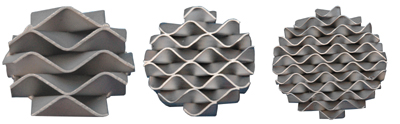

Figure #2: GV static mixer front view with 5-corrugated mixing plates across its diameter and a 45o corrugation angle relative to the pipe axis. |

||

|

|||

| Geometric Configuration Variables The GV static mixer is versatile because it has many geometric configuration variables that can be used to impact the intensity of mixing created within any given pipe diameter and create mixing solutions that are difficult to achieve with any other technology:

|

|||

Figure #3: The mixing intensity and pressure drop of the GV static mixer may be adjusted by varying the number of corrugated layers in any specific pipe diameter (left side: standard 5 layers; middle: 8-layers; right side: 12 layers). |

|||

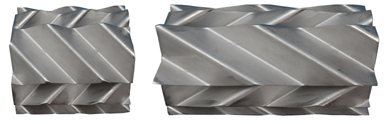

Figure #4: The mixing intensity and pressure drop of the GV static mixer can be adjusted by varying the corrugation angle relative to the pipe diameter (left side: standard 45o angle; right side: 30o angle) |

|||

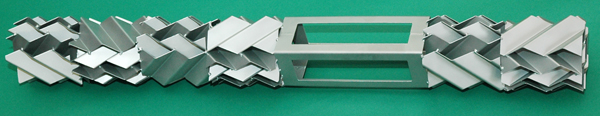

Figure #5: Spacers can be added between mixing elements to take advantage of the turbulent eddies created downstream of a mixing element at no additional pressure drop and at modest cost. |

|||

History of GV Static Mixing Structure * StaMixCo is not a distributor of or affiliated with Sulzer Chemtech. SMV is a brand and trademark of Sulzer Chemtech. More Information |

|||

Request A Quote | Mixer Selection Guide | Site Map

Mexico & South America: StaMixCo-Mexico; Geranios 26, J del Alba; C. Izcalli; 54750 Estado de Mexico; Tel: 52 (55) 2876 2311

USA & Canada: StaMixCo LLC; 235-84th Street; Brooklyn, New York 11209 U.S.A.: Tel: (718) 748-4600

Europe, Asia-Pacific, Africa: StaMixCo Technology Ltd.; Ebnetstrasse 8; CH-8474 Dinhard, Switzerland: Tel: +41 52 338 17 11

© 2008 StaMixCo, LLC. | Powered by Register.com