| X-Grid Static Mixer (Type GX) The GX static mixer has been used successfully for the laminar flow mixing and/or dispersion of viscous fluids for over 25 years. It is a high performance static mixer capable of mixing materials with equal or very large differences in viscosity and volumetric ratio. Mixing is accomplished in a short length with a very high degree of mixing. |

|

Figure #1: GX static mixer with 4-mixing elements

|

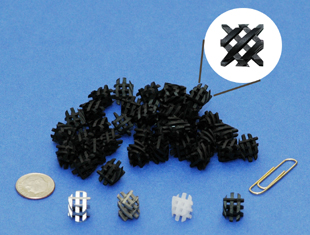

Figure #2: GX mixing elements are available in sizes as small as 9.8 mm (0.39”) diameter and in much larger standard and custom static mixer materials and sizes. |

Mixing Capabilities

|

Applications

|

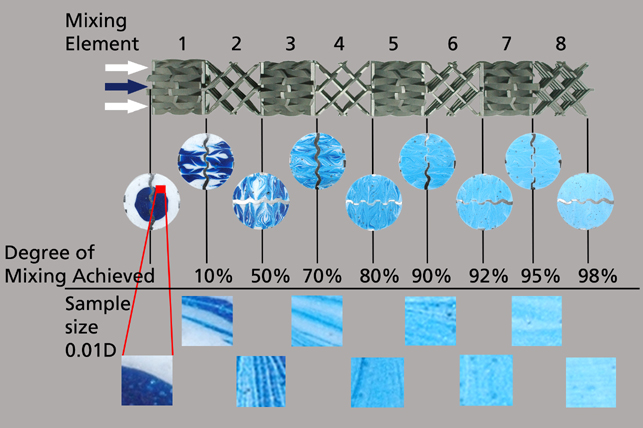

Figure #3: Homogeneous mixing with GX static mixing elements

Geometric Configuration Variables

The standard GX mixing element (Figures #1 -3) is constructed with 8-mixing bars across its diameter and with a 45o blade angle relative to the pipe axis. Depending on process requirements, the number of mixing bars and the blade angle can vary (Figures #4 - 5). |

|

| Geometric Configuration Variables The standard GX mixing element (Figures #1 -3) is constructed with 8-mixing bars across its diameter and with a 45o blade angle relative to the pipe axis. Depending on process requirements, the number of mixing bars and the blade angle can vary (Figures #4 - 5). |

|

Figure #4: GX-L static mixer with 4-mixing bars and a gentle 30o blade angle relative to pipe axis |

Figure #5: GX-LR static mixer with 4-mixing bars, a gentle 30o blade angle relative to the pipe axis and where each ellipse blade set is oriented 90o relative to the adjacent set. |

| Materials of Construction, Housings and End-Connections The GX static mixer can be supplied in most materials of construction, pipe/tube housings with virtually any end connection (Figure #6). GX-P mixing elements in 9.8 mm outside diameter size are also available in plastic construction (Figure #7). |

|

Figure #6: A typical GX inline mixing installation includes mounting inside a pipe with flanged ends, threaded ends or beveled ends prepared for welding |

Figure #7: Plastic GX-P mixing elements in 50% glass-filled Nylon and Polypropylene construction |

| History of GX Static Mixing Structure The X-Grid static mixer structure was invented by Bayer AG of Leverkusen, Germany in the early 1980's. Bayer used the X-Grid static mixer extensively in their polymer plants and subsequently licensed the design to Sulzer Chemtech of Winterthur, Switzerland who trademarked the design as the SMX* static mixer. Sulzer published a tremendous amount of fundamental high quality R&D work on the SMX structure and commercialized the SMX static mixer in tens-of-thousands of successful installations. The founders of StaMixCo held key technical and management positions in the Koch Engineering (USA) - Sulzer Chemtech (Switzerland) team that commercialized the SMX static mixer. Bayer licensed their 2nd generation version of the X-Grid static mixer to StaMixCo which is branded as the GXR static mixer with integral support ring around the X-Grid mixing bars (see StaMixCo GXR section of this web site). The GX static mixer in this web page is StaMixCo's version of the Sulzer SMX static mixer. * StaMixCo is not a distributor of or affiliated with Sulzer Chemtech. SMX is a brand and trademark of Sulzer Chemtech. More Information Technical Bulletin (pdf 736 kb) Customer Specification Questionnaire (Excel 33 kb) |

|

Home | Principles of Operation | Products | Applications & Industries | Technical Information | About Us | Contact Us

Request A Quote | Mixer Selection Guide | Site Map

Mexico & South America: StaMixCo-Mexico; Geranios 26, J del Alba; C. Izcalli; 54750 Estado de Mexico; Tel: 52 (55) 2876 2311

USA & Canada: StaMixCo LLC; 235-84th Street; Brooklyn, New York 11209 U.S.A.: Tel: (718) 748-4600

Europe, Asia-Pacific, Africa: StaMixCo Technology Ltd.; Ebnetstrasse 8; CH-8474 Dinhard, Switzerland: Tel: +41 52 338 17 11

© 2008 StaMixCo, LLC. | Powered by Register.com

Request A Quote | Mixer Selection Guide | Site Map

Mexico & South America: StaMixCo-Mexico; Geranios 26, J del Alba; C. Izcalli; 54750 Estado de Mexico; Tel: 52 (55) 2876 2311

USA & Canada: StaMixCo LLC; 235-84th Street; Brooklyn, New York 11209 U.S.A.: Tel: (718) 748-4600

Europe, Asia-Pacific, Africa: StaMixCo Technology Ltd.; Ebnetstrasse 8; CH-8474 Dinhard, Switzerland: Tel: +41 52 338 17 11

© 2008 StaMixCo, LLC. | Powered by Register.com