|

About Static Mixing Technology:

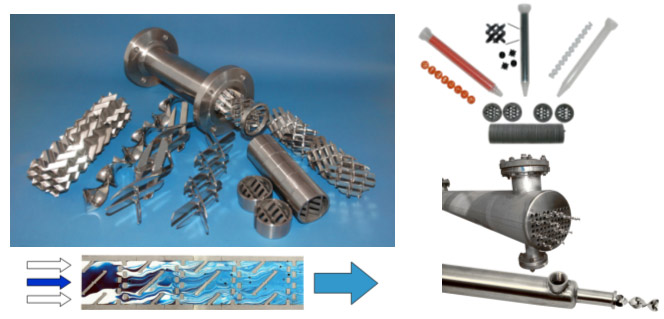

StaMixCo manufactures a wide variety of static mixer designs (motionless mixers) that mix materials with no moving parts. Materials to be mixed are pumped into the static mixer where their geometric structure forces the materials to continuously divide and recombine until a homogeneous material exits the static mixer. The static mixer design best suited for a specific application is process dependent...

• More Information (PDF-708 kb)

Key process areas and applications include:

• Viscous Material Processing: capabilities include the mixing and dispersion of materials with large differences in viscosity, volumetric ratio and temperature such as in plastics injection molding & extrusion, polymer and fiber manufacture, and for the processing of two-component adhesives, sealants, polyurethanes, polyols, liquid silicone rubber (LSR), etc. Applications beyond mixing include continuous plug flow reactors and enhancing the heating & cooling of viscous materials.

• Low Viscosity Material Processing: capabilities include the mixing of low viscosity fluids such as water-like liquids, gases and slurries as processed in the chemical, petrochemical, oil refining, gas processing, food, pharmaceutical and other industries.

• Multi-Phase Contacting: capabilities include contacting immiscible materials such as gases and liquids, and immiscible liquids to enhance dispersion, mass transfer, reaction and heat transfer.

StaMixCo Products for Mixing, Reaction & Heat Transfer Technology:

A brief description of our products and their technical performance follows:

|

Injection Molding Static Mixing Nozzle & Filter (Type SMN/SMF) The SMN Injection Molding Static Mixing Nozzle homogenizes molten polymer during injection. It creates a homogeneous mix with regard to colorant, additives and temperature. This assures reduced spots, streaks and clouds of color; reduced colorant usage; and uniform parts as a result of thermal homogenization. The optional SMF Filter is installed to protect the hot runner system and mold when processing regrind materials by avoiding clogging and/or damage with debris carried along with the feed pellets. • More Information (PDF - 411 kb) |

|

Extrusion Static Mixer Melt Blender (Type SMB) The SMB Extrusion Static Mixer Melt Blender homogenizes the polymer melt just in front of the die. Three types of commercially proven static mixer designs are available depending on process requirements. For high performance applications, the X-Grid crossing-bar static mixer designs creates a very high degree of mixing in a short length. For medium performance applications, the helical static mixer design creates a modest degree of mixing at a low pressure drop. • More Information (PDF - 1.13 MB) |

|

Double-Roof Disk Static Mixer (Type GXR) The GXR Double-Roof Disk static mixer is an X-Grid crossing bar structure with an integral ring around the mixing element grid. The entire unit is of monolithic cast construction (single molten metal pour) which makes the unit virtually indestructible. The GXR is considered a high performance design that homogenizes viscous materials in a short length. It is used extensively for plastics injection molding and extrusion and for the processing of viscous polymers and resins (Licensee of Bayer A.G., Leverkusen, Germany). • More Information (PDF - 340 kb) |

|

X-Grid Static Mixer (Type GX) The Type GX static mixer is constructed of X-Grid crossing bars. It has been used successfully for over 25 years for the mixing and/or dispersion of viscous fluids. The GX static mixer is considered a high performance design that homogenizes viscous materials in a short length and is capable of mixing materials with equal or very large differences in viscosity and volumetric flow rates. • More Information (PDF - 740 kb) |

|

Corrugated Plate Static Mixer (Type GV) The Type GV static mixer is constructed of offset-stacked corrugated plates. It has been used successfully for over 35 years for the mixing of low viscosity liquids, gases, immiscible liquid dispersions and gas-liquid dispersion and contacting. The GV is considered a high performance design for low viscosity fluids in turbulent flow applications where intimate contact and a homogeneous mixture are required in a short length. • More Information (PDF - 1.3 MB) |

|

Helical Static Mixer (Type HT) The Type HT static mixer is constructed of alternating-twist helical spirals. It pioneered the motionless mixing industry over 40 years ago and is used for the mixing of liquids, gases and slurries. The HT static mixer is considered a medium performance design that is best suited for small diameter simple mixing and heat transfer applications. |

|

Plastic Disposable Static Mixers Plastic Disposable static mixers for 2-component resin systems are available in both high and medium performance designs. High performance designs are based on the X-Grid geometric structure where a high degree of mixing is achieved in a short length and is ideal for difficult applications. For simple applications, the cost effective industry standard HT helical twist structure is available. Applications include the mixing of 2-component systems such as Epoxies, Urethanes, Liquid Silicone Rubber (LSR), Adhesives, Sealants, etc. • More Information (PDF - 756 kb) |

|

Heat Exchangers The heating and cooling of viscous materials in empty tubes is greatly enhanced by the use of static mixers. Static mixers decrease the boundary layer at the empty pipe wall and normally increase heat transfer by a factor of three to six. Depending on process requirements, heat exchangers are available in monotube and multi-tube configurations and with removable or fixed static mixing element types GX, GXL or HT. |

|

Plug Flow Polymerization Reactors Static Mixers create excellent radial mixing and plug flow conditions required to perform continuous chemical reactions with viscous materials. The resulting product of reaction has a uniform history with regards to time, viscosity, temperature and molecular weight. Depending on process requirements, a typical small to medium size plug flow reactor is rack mounted and sometimes jacketed with removable static mixing elements type GX or GXL. |

|

Laboratory Test Facilities and Computational Fluid Dynamics (CFD) Flow Modeling Laboratories for testing high viscosity polymers are available for extrusion, mixing, dispersion, devolatilization, reacting and heating/cooling. CFD modeling and physical pilot plant testing to verify CFD predictions are also available for large diameter gas mixing applications where injectors, turning vanes and rectifying grids must be retrofitted into existing ducting, catalytic reactors, empty vessels, Baghouses and electrostatic precipitators for systems that require good mixing, flat velocity profiles and low pressure drops. |

|

StaMixCo - México México & Central América StaMixCo LLC - México Geranios 26, J del Alba C. Izcalli 54750 Estado de México, México Tel: +52 (55) 2876 2311 Tel / Fax: +52 (55) 5873 8564 Website: www.stamixco-mex.com E-mail: info@stamixco-mex.com |

StaMixCo - USA North & South America StaMixCo LLC 235 – 84th Street Brooklyn, New York 11209 USA Tel: + (718) 748-4600 Fax: + (718) 833-8827 Website: www.stamixco.com E-mail: stamixco@msn.com |

StaMixCo - Switzerland Europe, Asia-Pacific, Africa StaMixCo Technology Ltd. Ebnetstrasse 8 CH-8474 Dinhard Switzerland Tel: +41 52 338 17 11 Fax: +41 52 338 17 33 Website: www.stamixco.com E-mail: info@stamixco.com |